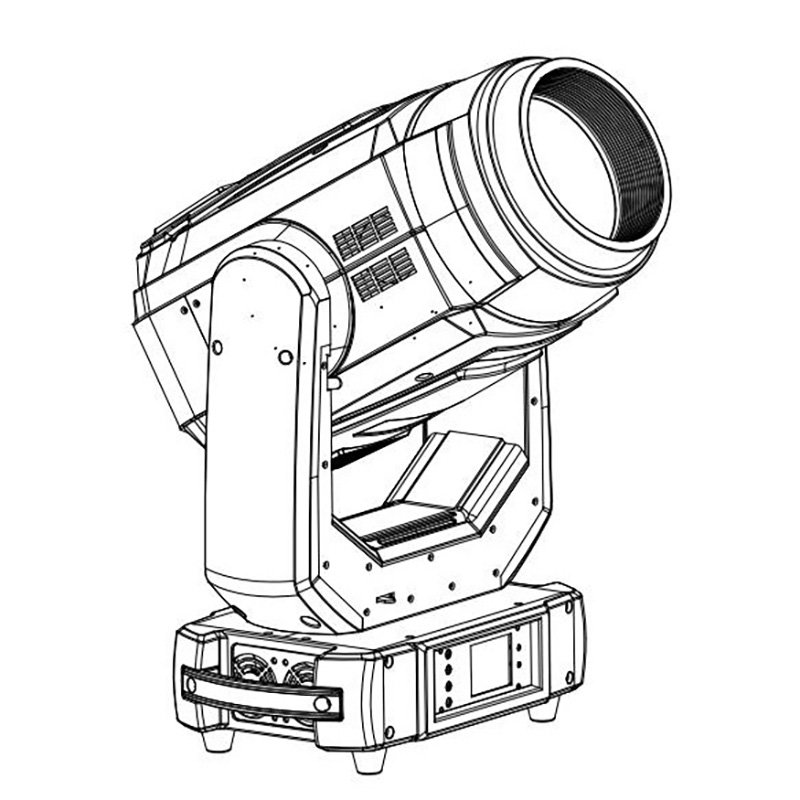

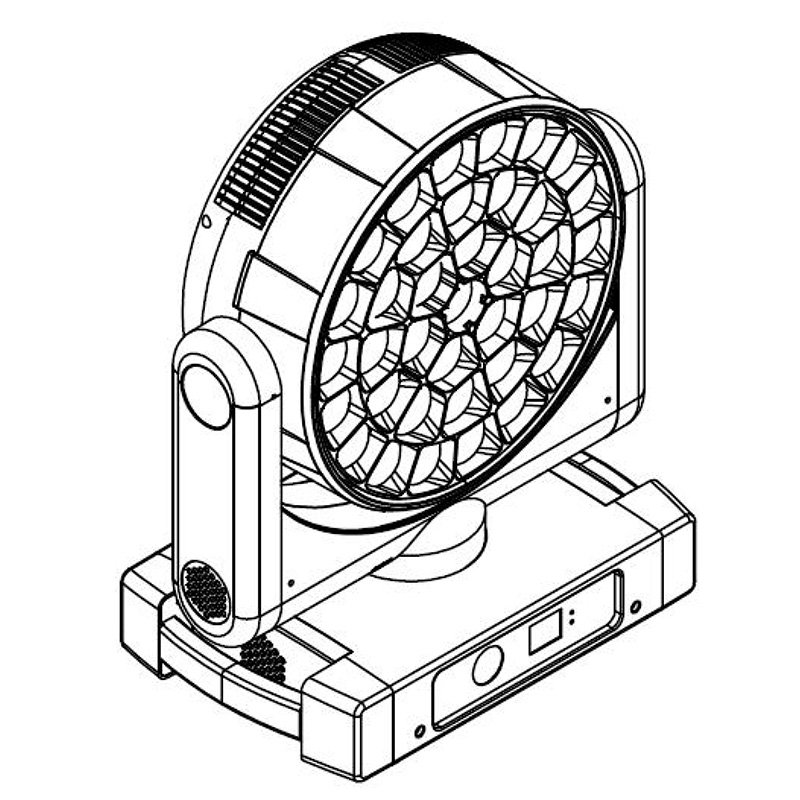

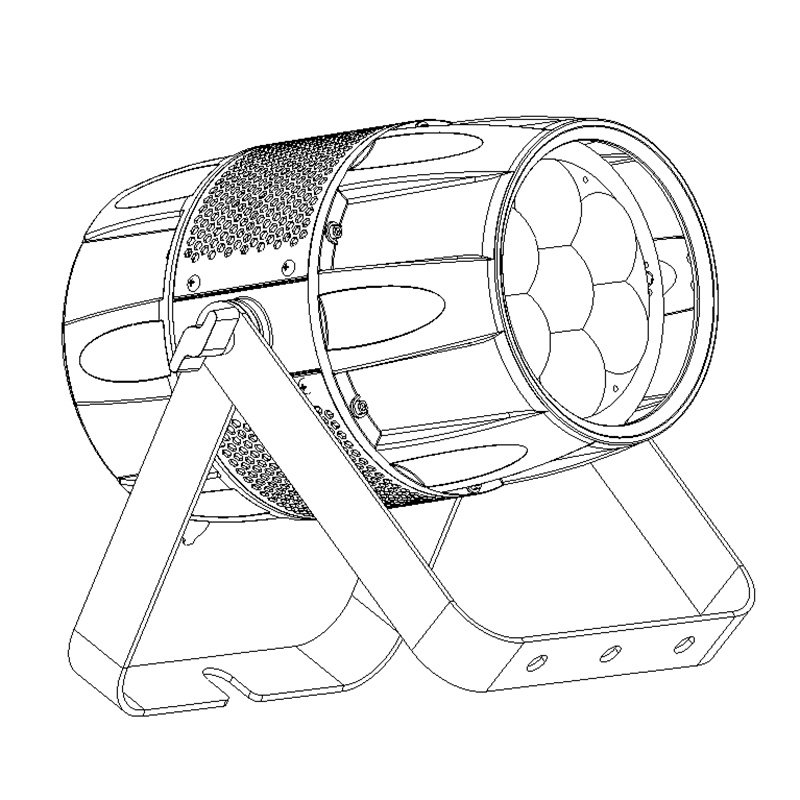

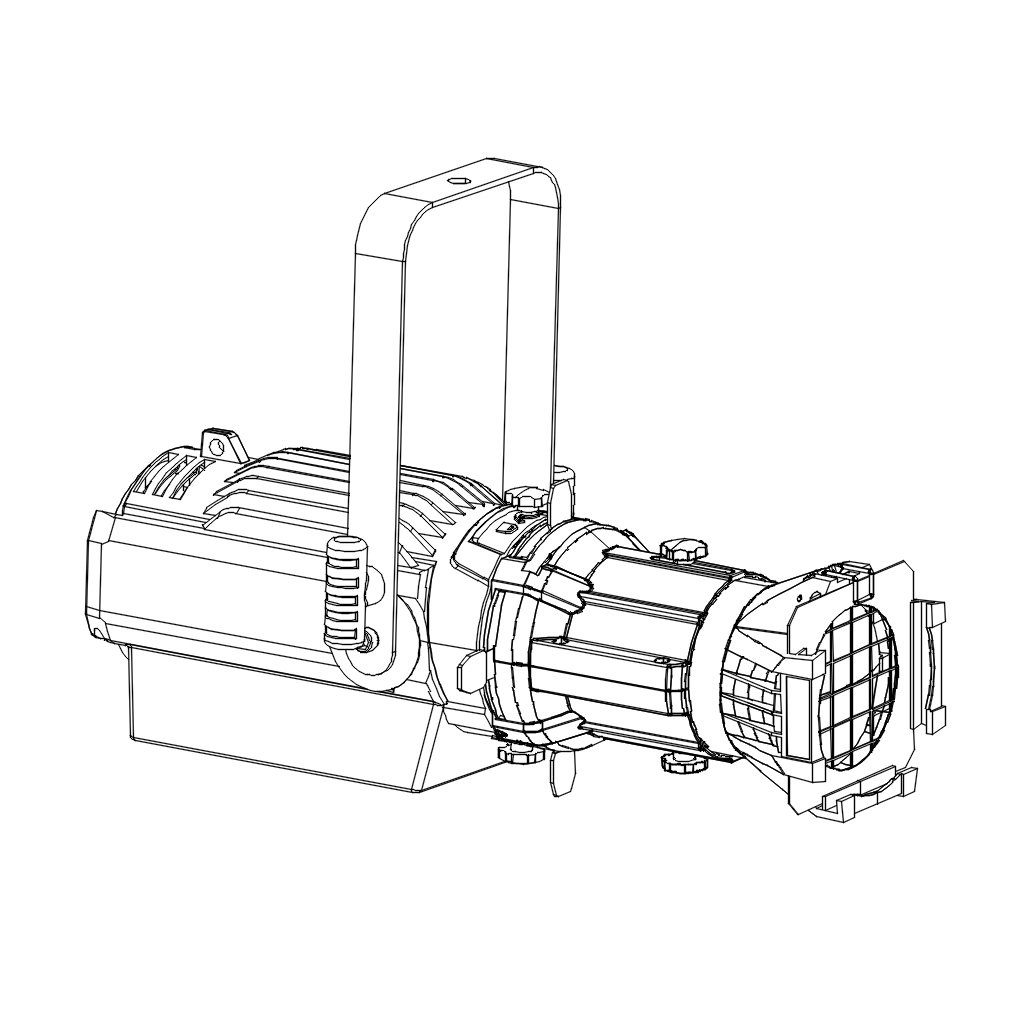

Moving head lights are a fantastic way to light up your stage. They have many benefits, including the ability to throw an even beam of light over a wide area and provide precise control of where you want it. However, these powerful lights need daily maintenance in order to keep them at their best. In this blog post we will talk about how to maintain your moving head lights so that they can continue to provide you with great lighting for years!

1. What are moving head lights and why should you care about them?

A moving head light is a type of stage lighting that has the ability to move its yoke vertically, horizontally or both. It can be used for many different applications including spotlights and flood lights. Moving head lights are used in many situations, including concerts, shows, dance floors and other entertainment features.

It has high requirements on the environment, transportation, and use, so its failure rate is also high. Therefore, daily maintenance of moving head light is important for moving head lights! A failed moving light may ruin your show or cause great accedents. So, let's learn more about moving head light daily maintenance!

2. Why it's important to maintain your moving head lights

Daily maintenance of your moving head lights is important because it keeps them in good condition. If you don't maintain them, the lights will eventually wear out and you'll need to replace them. Maintaining your moving head lights also ensures that they're functioning properly and that you're safe when using them.

3. How to keep your lights in good condition

There are a few things that you can do to keep your moving head light in good condition.

First, make sure to keep the light clean. You can do this by wiping it down with a cloth or a damp paper towel.

Parts with coated color films and optical lenses, because the surface of the coating layer is very brittle and easily scratched, so do not use destructive solvents for cleaning;

Second, after each show, use the air gun to blow off the lens and every crevice of the dust that may appear, or other debris left after the use of the stage effects machine.

Third, cover the light well and store in dry warehouse when it's not in use. Keep away from dust and humid environment.

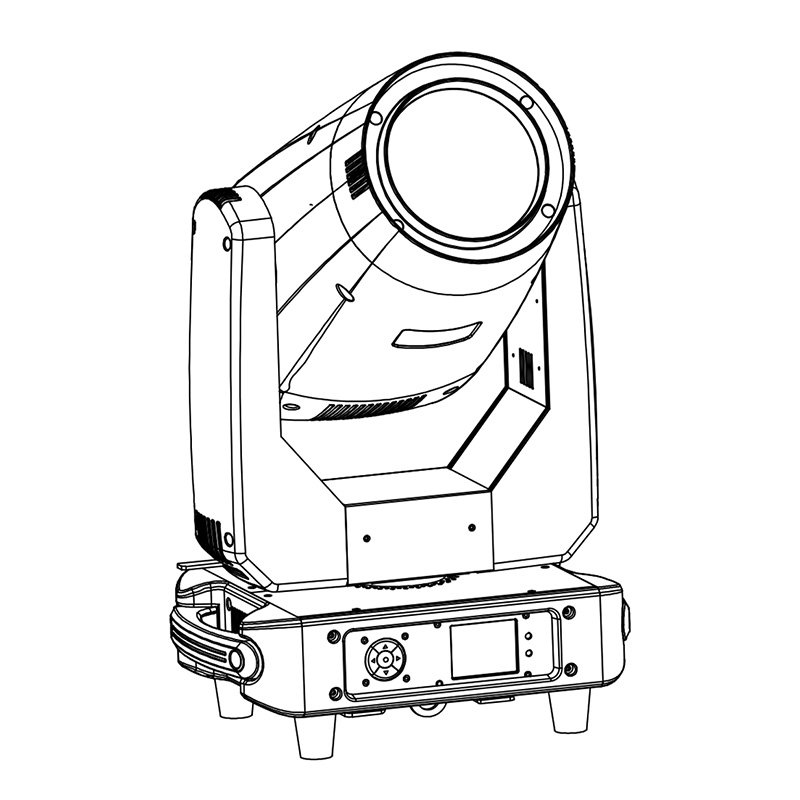

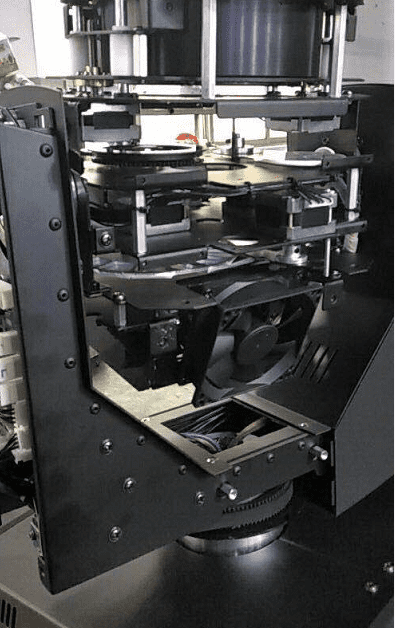

Fourth, after a period of use, make sure you open the plastic cover of the head and check the inside of the light.

Checking points for the inside

Here are some checking points for the inside of the moving head:

-Check the wires to make sure they're all connected and in good condition.

-Make sure that there's no dirt or debris blocking the light path.

-Check the pcb boards and connectors to make sure they're all in good condition.

-Check the lamp and reflector to make sure they're both in good condition.

-Check the motors and other components to make sure they're all in good condition.

The beam light basically uses a switching power supply to transform, which communicates with the traditional inductance transformer.

Because the switching power supply is used, the stability of the control circuit of the subsequent stage is greatly enhanced.

Due to the high technical difficulty of switching power supplies, the failure rate will be higher than that of inductive transformers.

Because it uses a switching power supply, the moving light is not affected by changes in external voltage, and can be input at full voltage (110V-240V), and the problem of voltage instability does not exist.

4.Common failure and solutions

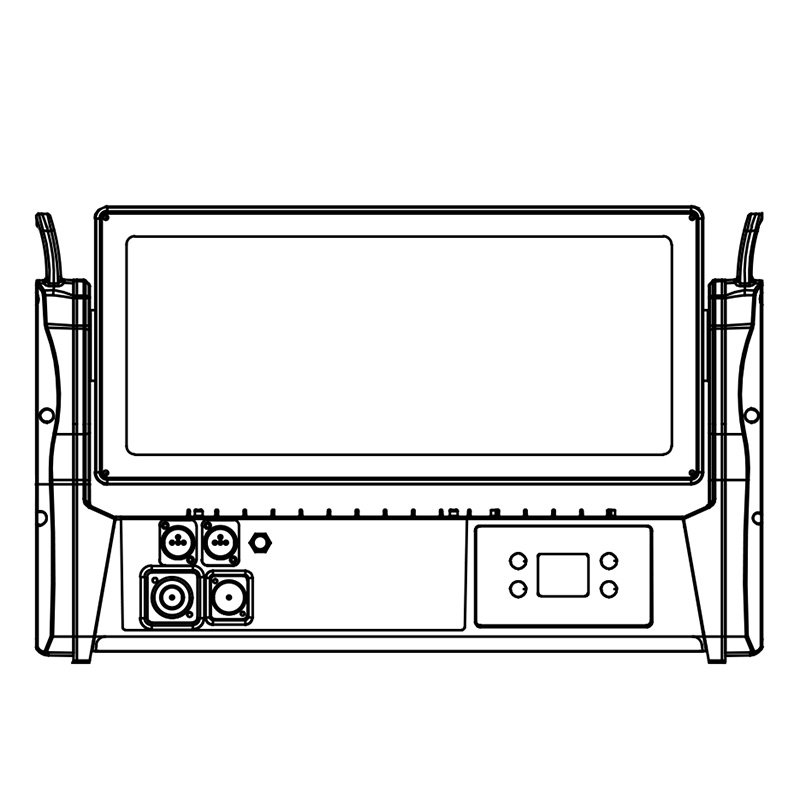

No response at when power on

- Whether the power supply is normal and whether the power cord of the lamp is off;

- Whether the fuse of the lamp is burned out;

- Whether the switching power supply of the lamp has output voltage.

Bulb does not light up

- First judge the quality of the bulb, check whether the bulb's foam core contacts are burnt, and whether the bulb itself is broken.

- Make sure that when the lamp is in the state of ignition, measure whether the output of the ignition voltage of the main board is normal. Normally, the voltage is generally 10-12 volts.

- If the above two points are correct, measure whether the PFC output (input end of the lighter) has an AC voltage output of about 380V. If there is an output, it indicates that the PFC is good, so you can directly determine whether the lighter has a problem.

Bulb reset periodically

- The output voltage of the switching power supply is unstable;

- The wire in the line is loose or the wire is not pressed tightly, resulting in poor contact and automatic reset.

Bulb automatically off

- The bulb is off, and it will automatically turn on after a period of time. Check whether the heat dissipation system is working properly. If the heat dissipation system fails, the temperature inside the lamp will be too high, and the temperature control switch will automatically trip to ensure the safe use of the lamp. When the electronic lighting is off, the lamp will automatically light up when the temperature of the lamp body drops.

- After the bulb is extinguished, the bulb cannot be automatically lit: the bulb itself is a problem, the bulb sphere surface is white, the inside is black, and the phenomenon of extinguishing the bulb will appear after the bulb is lit for a period of time (the bulb life ends).

- When the lamp has no control signal for a long time, the automatic protection of the gun will appear, and the lamp will be automatically lighted after the signal is turned on.

The gobo wheel, color wheel, prism, and focus are stuck, jittered, and out of step

- The jam is usually caused by mechanical reasons. At this time, the color film jam will occur: such as the pattern plate, the deformation of the color plate, the loosening of the fixing part screw, the spring of the fixed pattern, etc., will cause the jam. appear.

- Shaking and out-of-step: the screw is loose or falling off, the chip of the channel on the motherboard is burned out, the motor wire is poorly connected, the broken skin is short-circuited to the ground, and the motor itself is faulty.

Horizontal and vertical (X/Y axis) out of step, no positioning

- There is too much dust on the light lotus root, which makes the infrared light unable to be controlled in place;

- The light lotus root plate is damaged, and the distance between the light lotus root plate and the light lotus root is improperly adjusted.

The above is the analysis of the causes of some common failures.

Other precautions for daily use

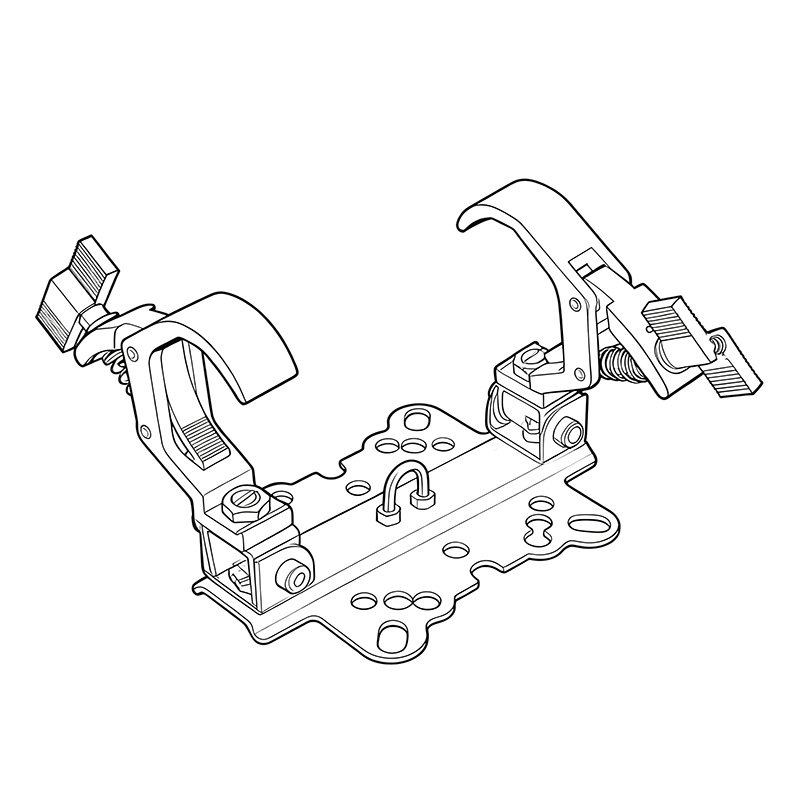

The beam light should be handled gently to avoid collisions, falls, etc.;

Be careful not to use it in places with a lot of wind, sand and dust, or use high-quality products, and clean it in time. After the performance, use the console to extinguish the bulb, and let the lamp continue to work for a period of time without cutting off the power supply (let the fan in the lamp continue to work to reduce the temperature inside the lamp);

After the performance of mobility, it should be put into a special air box to prevent moisture and shock, and the fixed beam light should be protected from dust and impact.

In order to maintain a moving head light, it is important to clean the lens from harm from dirt from the road. The manufacturer recommends regular lubrication of the gears and suspension of the moving head light. It is also necessary to replace the brass bushings that surround the motor with a softer material which will wear more evenly and last longer.

A regular service of a qualified technician for this line of products will help keep your moving-head lights operating at their optimum level.