Recently, during the pro-light and sound exhibition, there was a fire accident during the lighting show, a moving head light caught fire. This caused the attention of the lighting designer, manufacturer as well as the audience. As we all know, the fire is fatal to the show and everybody. So, how to prevent the stage lighting from these dangerous factors and how to choose a proper stage light?

Here are some points you should consider before you make up your decision:

The most important is: Choose the right lighting fixture.

Firstly, always purchase from a qualified factory.

When you are deciding to buy a new lighting fixture, you should consider these points, is it a qualified factory? A qualified factory should have the legal registration from the government. Is it CE or RoHS certified? Nowadays the competition is very high in the market, some factories make the incredible lowest price in the market and replace the material with repeated plastic.

A series of fires show that the fire protection design of stage lighting is very important. So, how can stage lighting fire protection design be recognized as qualified through fire safety inspection?

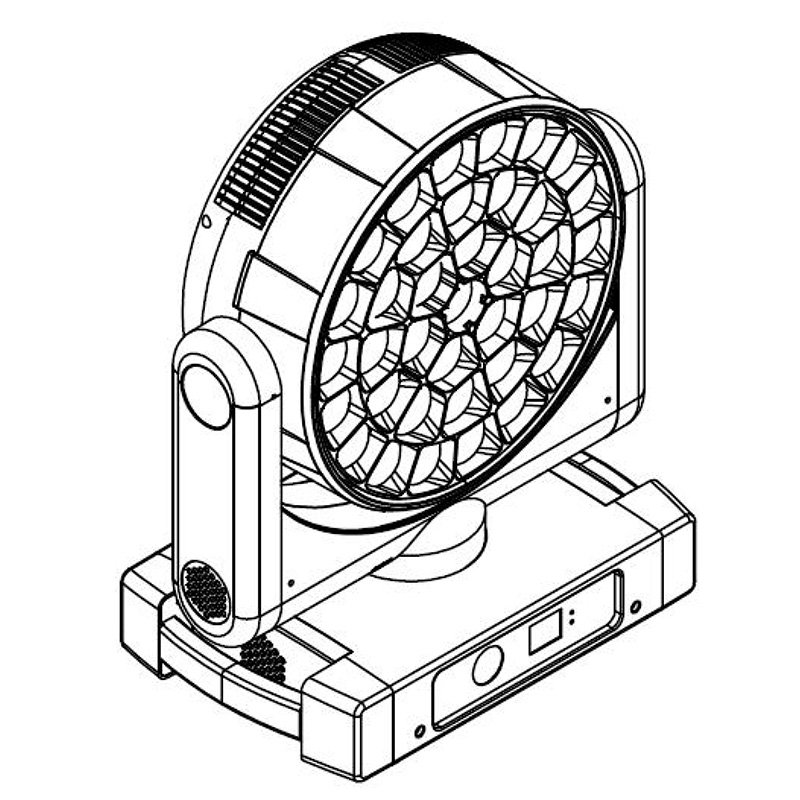

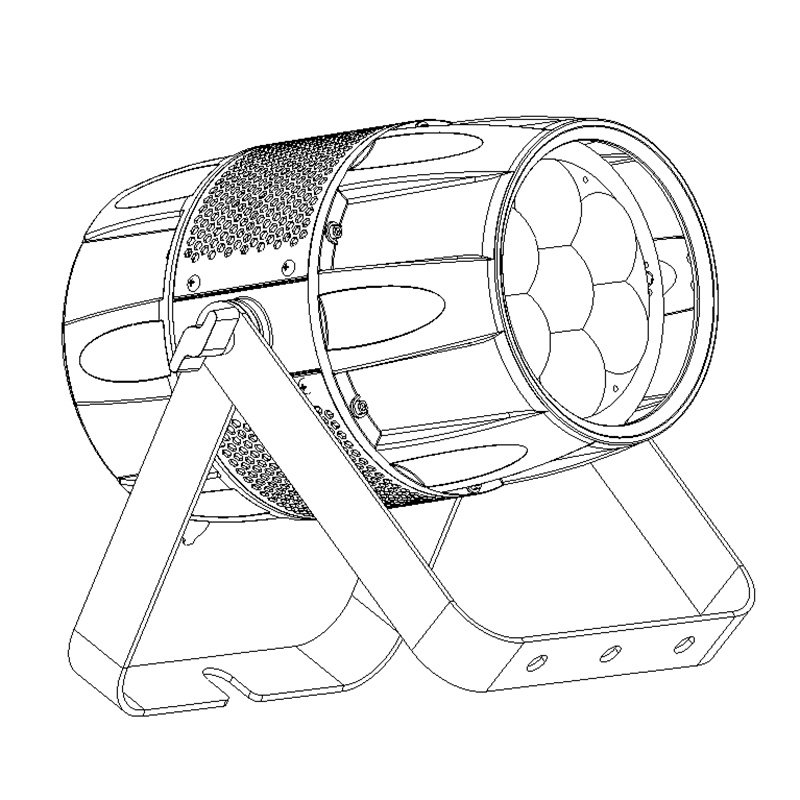

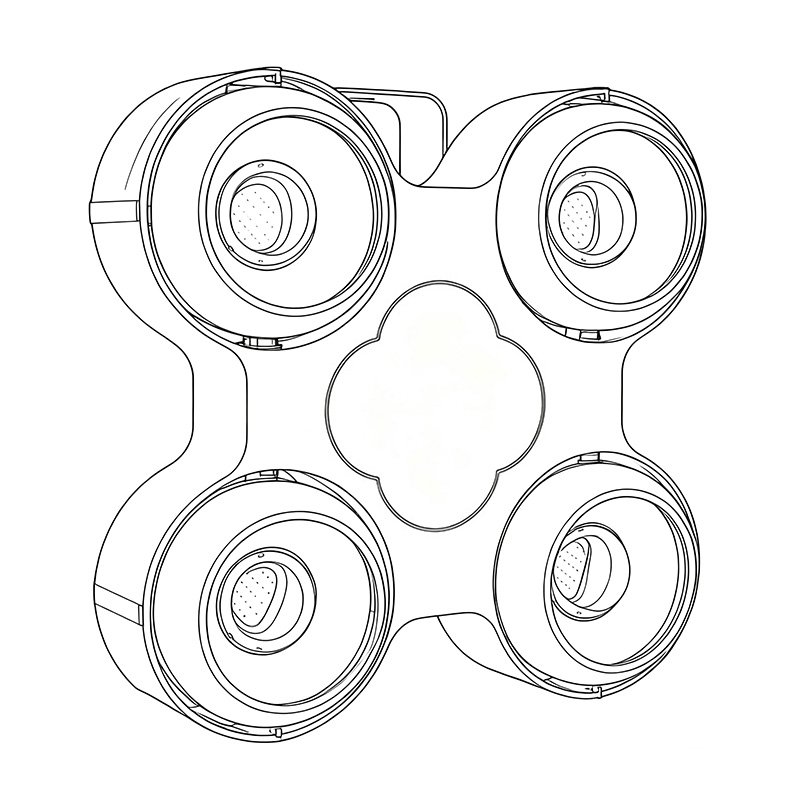

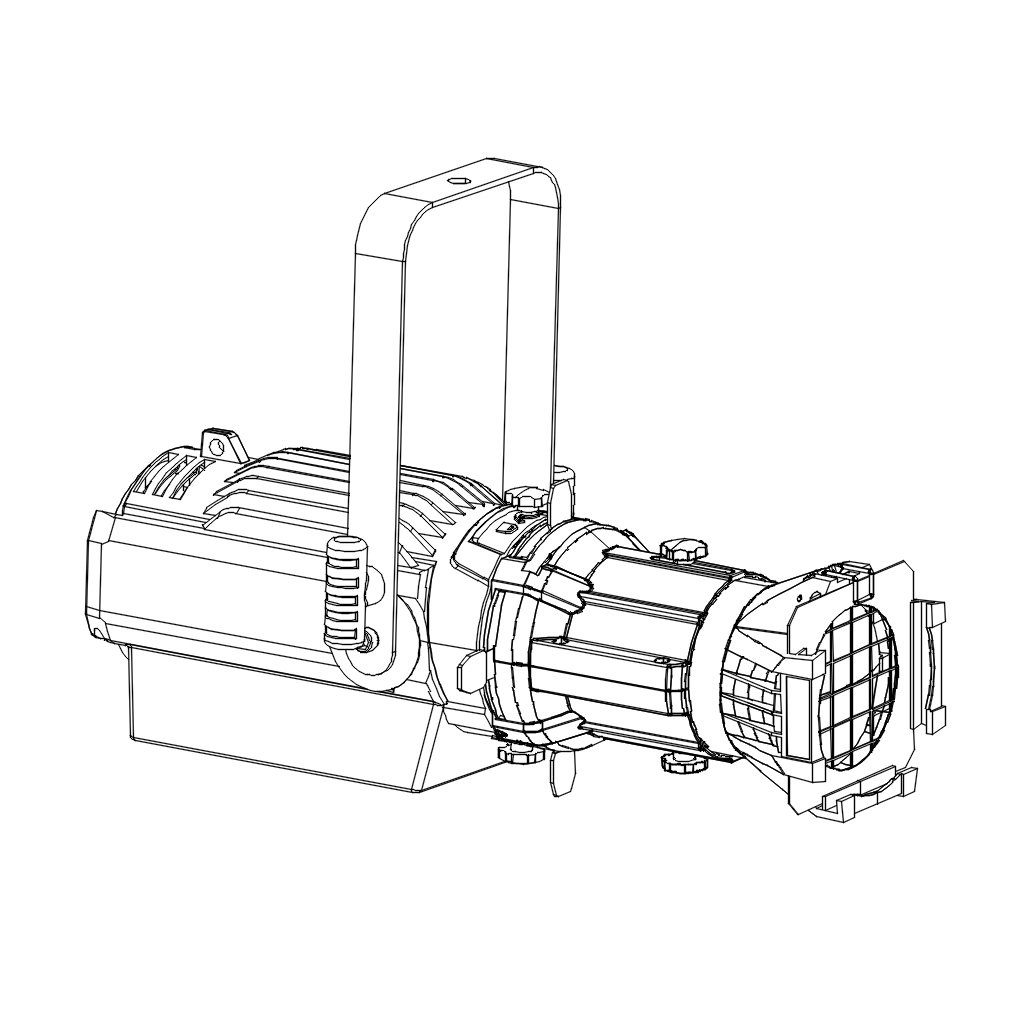

Reasonable selection of lamp types.

In places where explosive mixtures or explosive media are likely to be produced during production, integral explosion-proof devices should be used. For places with corrosive gas and particularly humid places, sealed or moisture-proof lamps should be used, and their parts should also be treated with anti-corrosion. Floodlights can be used in hot and dusty places (such as steelmaking, ironmaking, steel rolling, etc.). Outdoor lighting can be enclosed type lamps or open type lamps with fireproof lamp holders.

Lighting and decorative lamps should be installed correctly.

(1) The distance between the lamp and combustible material is not less than 50 cm (more than 50 cm for tungsten halogen lamps), and the height from the ground should not be less than 2 meters. When it is lower than this height, protective facilities should be installed. It is not suitable to stack combustible materials under the bulb.

(2) The protective cover of the lamp must be intact. It is strictly forbidden to cover the lamp with paper, cloth or other combustible materials.

(3) The power of all concealed and surface-mounted lamps on the combustible ceiling should not be too high, and should be mainly incandescent or fluorescent; the concealed lamps and their heating accessories should have good heat dissipation conditions. The wires of the stage concealed colored lights, dance floor footlights, and combustible ceiling lamps should be laid through steel pipes or flame-retardant hard plastic sleeves; the wires near the halogen tungsten lamp tubes should be heat-resistant insulating sheaths; the wires of the hoisting colored lights There should be rubber ring protection when passing through the keel.

(4) Use reliable low-temperature ballasts. It is forbidden to directly fix high-temperature ballasts on flammable large plates and other objects. Its capacitance and capacity must be consistent with the lamp tube.

(5) Class 0 and Class 10 explosion hazard locations (Class 0 area refers to explosive gas, and Class 10 area refers to explosive dust). When an open-type lamp is used to make a wall-mounted niche, the access door should face outside the wall Turn it on and ensure good ventilation; the side facing the indoor lighting should be tightly sealed with double glass. The horizontal distance from the door and window frame is not less than 3 meters, and the horizontal distance from the exhaust outlet is not less than 5 meters.

Reasonably control electric lighting.

The lighting current should have its own branch circuit, and should not be connected after the main power switch. Each branch circuit must be equipped with short-circuit protection facilities. In order to avoid accidents caused by overload heating, some important places and places where flammable and explosive materials are concentrated must also be equipped with overload protection devices. Non-explosion-proof lighting distribution boxes and control switches are strictly forbidden to be used in explosion-hazardous locations of level 0 and 10. Minimize the joints behind the switchboard, and the panel surface should be well grounded.

Strict lighting voltage level and load capacity.

The lighting voltage is generally 220 volts, the power supply voltage of portable lighting fixtures should not exceed 36 volts, and it should not exceed 12 volts when operating in humid areas, and the use of autotransformers is prohibited. The power sockets below 36 volts and above 220 volts should have obvious differences and markings.

The number of lamps in a branch circuit should not exceed 20, the current for civil lighting should be less than 15A, and the current for industrial use should be less than 20A. The wire size is determined by the load (each socket is based on a load of 2 to 3 amperes). The three-phase four-wire lighting circuit should also be configured to balance the three-phase load.

Accident lighting fixtures should be located in places prone to accidents, main entrances and exits of buildings, important workplaces and other places, and marked with obvious color marks to prepare for timely and convenient use in the event of an accident. Emergency lighting fixtures can not be used to start slowly (such as ballast start lamps, etc.). The emergency lighting fixture should be powered by an independent emergency battery to ensure that it can be turned on and used normally when the normal power system is damaged.